- Do you need help? Here Us:

- +86 13169905499

- sunny@handaseal.com

- Wechat:13169905499

Chenzhou, Hunan, China(423000))

Our Spring Energizer Types

Handa Seal offers a full spectrum of spring energizer profiles, each engineered for a specific balance of sealing force, deflection control, space constraints, and media compatibility. Whether your application demands dynamic sealing at high pressures or static sealing in chemically aggressive environments, our spring types are designed to meet the challenge.

Helical Spring

Canted Coil Springs

Cantilever V Spring

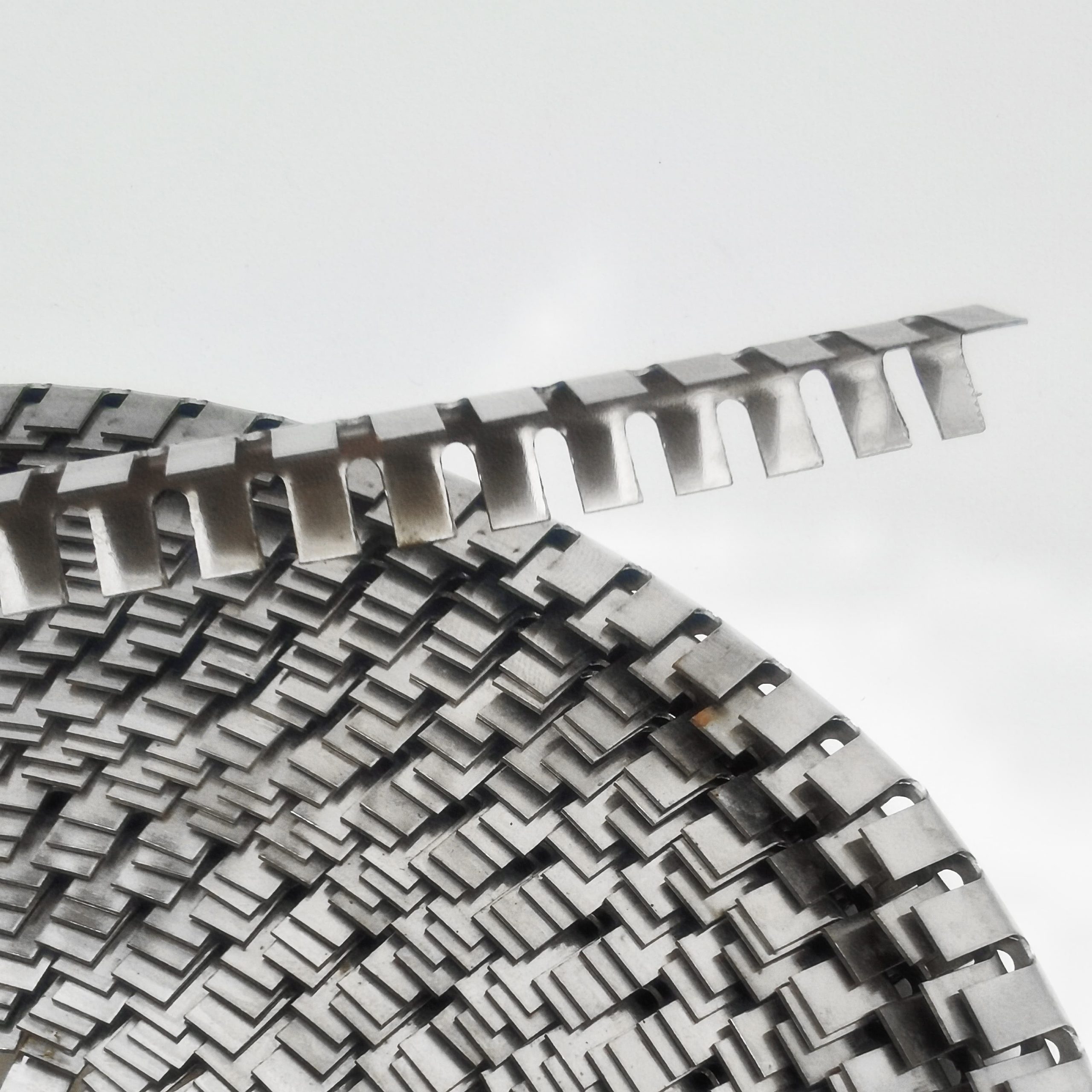

Cantilever U Spring

Full Contact Springs

Garter (Oil & Gas) Springs

Claim Your Free Sample Now!!!

Custom Spring Energizers

In addition to standard sizes, we also have over 100 different cross-sections of cantilever U and V springs available with little to no tooling cost to you. We can provide the exact quantities you need, reducing your investment in excessive inventory. Our combined material purchasing power ensures that we can stock specialty materials that are expensive and generally require longer lead times with other manufacturers. Having these alloys ready for production allows us to offer the best price and shortest lead times available. That’s why so many leading companies choose Handa.

We also perform spring energizer welding in-house. Review Features and Benefits of Welded Springs vs. Non-Welding Springs, to determine which is right for your application.

Request a quote to send us your specs or configure a part.

Materials

Handa stocks standard and specialty materials of all types. Below are some commonly requested materials used to manufacture spring energizer products. If your application requires alternate materials, contact us for custom quote information.

Related Manufacturing Services

Handa offers many optional secondary machining and finishing services for this product type. If you need additional services, contact us for more details. contact us for more details.

Spring Energizer Selection Guide

Choosing the right spring energizer is critical to ensuring long-term sealing performance under mechanical, thermal, and chemical stress. Handa Seal offers a diverse portfolio of spring types, each engineered for specific sealing dynamics—from low-friction dynamic motion to ultra-high-load static conditions.

| Spring Type | Spring Load | Deflection Range | Friction Level | Key Advantages | Typical Applications |

|---|---|---|---|---|---|

| Cantilever V-Spring | Medium | Medium | Moderate | Broad versatility; high sealing force | Aircraft engines, medical pumps, oil tools |

| Cantilever U-Spring | Low-Medium | Wide | Low | Moderate sealing force; good for vacuum and dynamic sealing | Hydraulic actuators, pneumatic valves |

| Helical Spring | High | Low | High | Highest load in small space; great for static and cryogenic | Space systems, vacuum chambers |

| Canted Coil Spring | Medium | Wide | Very Low | Uniform force over long deflection; fatigue resistant | Rotary shafts, medical tools, connectors |

| Full Contact Spring | Very High | Low | High | Continuous high force; best for gas and cryogenic | LNG, hydrogen systems, aerospace seals |

| Oil & Gas Spring | High | Medium–Wide | Moderate–High | Engineered for HPHT; corrosion and sour gas resistance (NACE compliant) | Downhole tools, blowout preventers, subsea valves |

For more specific needs or further customization, consulting with a specialist or referring to detailed technical specifications from the manufacturer is recommended.

Handa Spring Energizers: Reliable Seal Solutions for Extreme Temperatures, Corrosion & High Pressure

- Temperature extremes

- Problem: Seal force changes or spring relaxation at cryogenic or very high temperatures.

- Our solution: Use material-matched alloys (from Elgiloy/MP35N for low-temp stability to Inconel family for high-temp resilience) and controlled heat treatments.

- Benefit: Stable elastic response from cryogenic conditions up to several hundred °C (material dependent), preserving preload and seal integrity

- Corrosion & aggressive media

- Problem: Acidic, alkaline, chloride or sour-gas media cause corrosion and premature failure.

- Our solution: Specify corrosion-resistant alloys (Hastelloy, Elgiloy, Monel, MP35N) and protective surface finishes as required.

- Benefit: Long service life in chemical, offshore and process environments — less downtime and maintenance.

- Customization & delivery

- Problem:Off-the-shelf springs don’t match unique seal geometries.

- Our solution: Customize wire, pitch, free length, pre-load and finish; rapid prototyping and small-lot production.

- Benefit: Faster design iterations and quicker time-to-market for your sealing system.

- High pressure & mechanical load

- Problem:Loss of sealing under high system pressures or shock loads.

- Our solution:High-strength wire, optimized coil geometry and full-contact designs for increased radial force.

- Benefit:Reliable sealing in HPHT and subsea applications; maintains seal under extreme loads.

- Fatigue & lifetime (cycle life)

- Problem:Repeated cycling causes relaxation, creep, or fatigue fracture

- Our solution:Material selection and geometry tuned for high cycle fatigue (Elgiloy, MP35N); strict QC on forming and stress-relief.

- Benefit:Extended operational life in dynamic seals — fewer replacements and predictable maintenance windows.

- Space & integration constraints

- Problem:Limited gland/slot space demands high load in small volume.

- Our solution: Helical geometry optimized for load-per-volume (wire size, pitch, turns).

- Benefit: Achieve target preload in compact designs without enlarging seal hardware.

- Compliance & traceability

- Problem: Regulated industries require material traceability and certifications.

- Our solution: Material certificates, testing options (NACE, ISO, RoHS; medical-grade options available) and batch traceability.

- Benefit: Easier qualification for aerospace, medical and oil & gas projects.

中文 (中国)

中文 (中国)  English

English