- Do you need help? Here Us:

- +86 13169905499

- sunny@handaseal.com

- Wechat:13169905499

Chenzhou, Hunan, China(423000))

Garter Spring Overview

Handa’s Oil Seal Springs are purpose-designed metallic springs used to energize oil seals in demanding environments. By maintaining optimal lip pressure against shafts or housings, they prevent oil leakage—even at high speeds, under heavy loads, and across wide temperature ranges. Ideal for industrial machinery, automotive systems, marine applications, and power generation equipment, these springs ensure reliability in mission-critical applications.Elgiloy®, Stainless Steel, ensuring excellent corrosion resistance, fatigue life, and sealing reliability in demanding environments.

Typical Range of Application

Values and ratings in this catalog are based on industry standard applications operating under ideal conditions. The customer should assume responsiblity for validation testing of performance and suitabilty of Handa products. Handa Spring accepts no liabilty for the accuracy and applicabilty of provided information.

Pressure

Vacuum to 3,000 psi

[0 to 200 bar]

Temperature*

-418°F to 1472°F

[-250°C to 800°C]

Ratings will vary based on materials and operating conditions

Cusom Garter Springs

At Handa Spring, we specialize in custom oil seal springs (garter springs) engineered to deliver precise sealing performance. Every spring is manufactured to meet your exact design—diameter, wire size, spring force, and material selection are fully customizable.

Whether you need standard stainless steel (301/302/316), or advanced alloys like Inconel® or Elgiloy®, our team ensures durability in demanding environments such as automotive, pumps, compressors, and industrial machinery.

We provide fast prototyping, free samples, and no minimum order quantity, helping you achieve leak-tight sealing solutions with reduced lead time. Partner with us for springs tailored to your oil seal designs—reliable, precise, and built to perform.

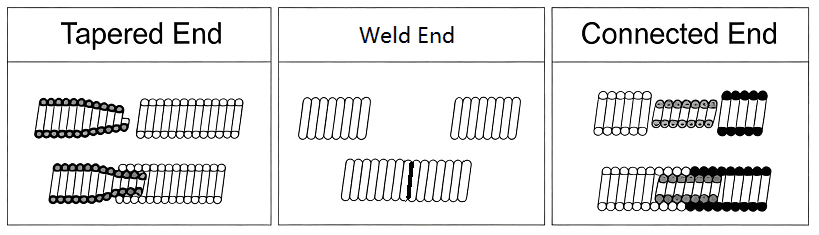

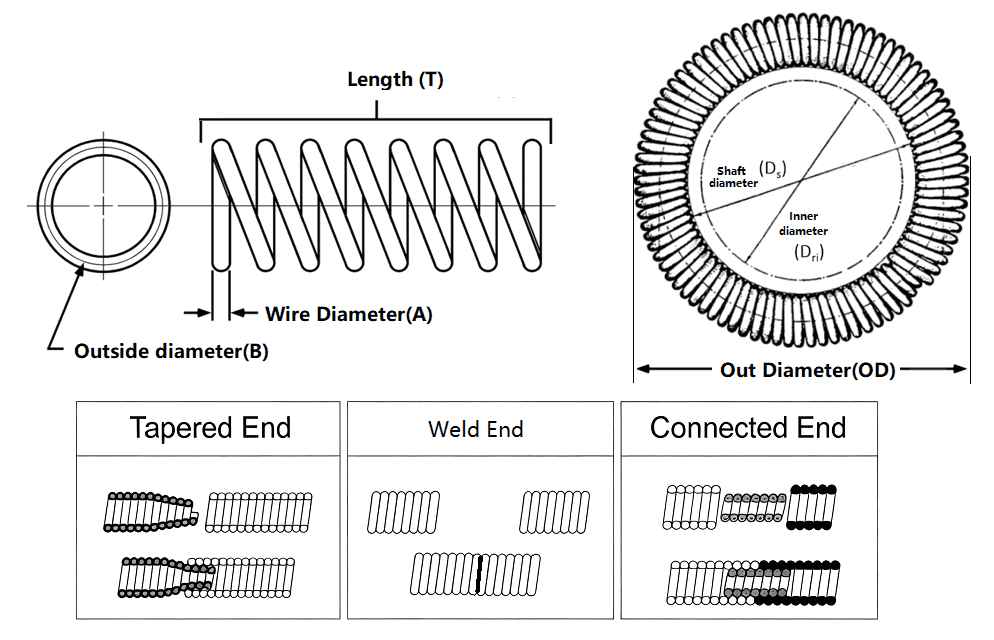

Several Ways To Connect the ends

The manufacturing process is not much different from the creation of regular coiled springs, with the addition of joining the ends together.

This can be accomplished through a few different ways:

- Laser-Welded End: Laser-welded oil seal springs deliver strong joints, enhanced durability, and precise sealing performance, ensuring reliability and long service life in demanding industrial applications.

- Tapered End: Reducing the diameter on one end of the spring so that it fits into the other end (nib joint). This is the most common method used. It is crucial to back-wind the spring to prevent twisting tension that could deform the spring.

- Connected End: Interlocking the loops at both ends of the spring through a smaller springs or rod.

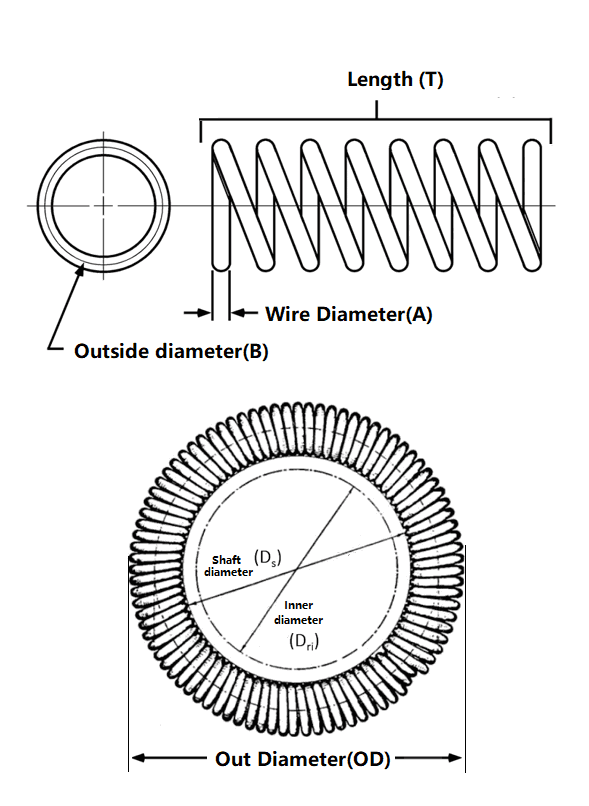

Garter Spring Dimensional

| Series | Wire Range A(mm) |

Outside Diameter B(mm) |

Out Diameter OD(mm) |

|---|---|---|---|

| HDY-GS-000 | 0.08 – 0.2 | 0.80 – 1.02 | Fully Customizable at No Extra Cost |

| HDY-GS-100 | 0.20 – 0.3 | 1.02 – 1.57 | |

| HDY-GS-200 | 0.3 – 0.4 | 1.57 – 1.98 | |

| HDY-GS-300 | 0.4 – 0.5 | 1.98 – 3.18 | |

| HDY-GS-400 | 0.5 – 0.6 | 3.18 – 6.35 | |

| HDY-GS-500 | 0.6 – 0.7 | 6.35 – 8.00 | |

| HDY-GS-600 | 0.7 – 0.8 | 8.00 – 10.2 | |

| Wire Range 0.05MM to 1.50MM | |||

You can also contact engineers for customization.

We can produce custom-made slant coil springs in nearly any size based on your samples or drawings.

The table is a part of specification size, more specifications please see attached. You can also contact engineers for customization.

Materials & Finish

Our Handa Cantilever spring is available in a variety of materials and surface finishes to meet specific performance demands. To reduce the potential for corrosion between dissimilar metals, we can plate springs with a galvanically compatible material.

Wire Materials Include:

- STAINLESS STEEL (302, 316, 304, 316, 316L)

- HASTELLOY®

- INCONEL®

- Elgiloy®

Finish Include:

- Plating

- Heat Treatments

- Laser Welding

Why Partner With Us?

Free Mold Opening

After-Sales Support

Customization Service

🚀 Ready to Specify Your Oil Seal Spring?

Handa Seal collaborates directly with engineering teams to optimize spring design and performance for B2B applications. We offer fast quotes, in-depth technical guidance, and flexible production volumes to fit your project timeline and specifications.

🚀Frequently Asked Questions

Q1. How do I select the right force and size?

A: We collaborate with your engineering team to analyze shaft speed, pressure, and operating temps to recommend optimal spring design.

Q2. Can you supply pre-assembled springs inside seal jackets?

A: Yes, we can deliver springs already assembled inside PTFE or polymer jackets, ready for your seal housings.

Q3. What is the lead time for prototypes and mass production?

A: Prototype turns typically in 5–7 days; standard mass production within 1–2 weeks. Expedited lead times available.

Q4. Are material certifications available?

A: Yes, we provide material certificates (e.g., 3.1, 3.2), and can comply with RoHS, REACH, and ISO/AS9100.

中文 (中国)

中文 (中国)  English

English