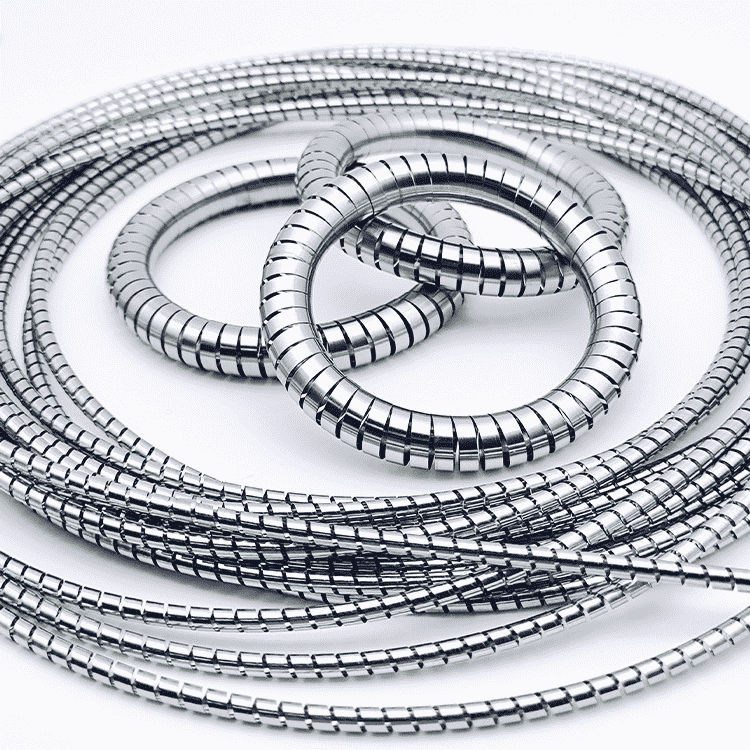

Reference the below to find dimensions for our standard Helical springs. Custom diameters, widths, and thicknesses can also be created. No additional tooling charges are required for special diameters or alternate material slit widths. Special material requirements for 17-7 PH Stainless,Elgiloy are available and can be supplied in two weeks or less.

| SERIES | S(Outside diameter) | H(Width) | C(Material thickness) |

|---|---|---|---|

| HDY-SHE-152038010 | 1.52mm | .06″ | 0.38mm | .015″ | 0.10mm | .0039″ |

| HDY-SHE-200150010 | 2.00mm | .079″ | 1.50mm | .059″ | 0.10mm | .0039″ |

| HDY-SHE-229051013 | 2.29mm | .09″ | 0.51mm | .02″ | 0.13mm | .005″ |

| HDY-SHE-250150010 | 2.50mm | .098″ | 1.50mm | .059″ | 0.10mm | .0039″ |

| HDY-SHE-300150010 | 3.00mm | .118″ | 1.50mm | .059″ | 0.10mm | .0039″ |

| HDY-SHE-318064020 | 3.18mm | .125″ | 0.64mm | .025″ | 0.20mm | .0079″ |

| HDY-SHE-318150015 | 3.18mm | .125″ | 1.50mm | .059″ | 0.15mm | .0059″ |

| HDY-SHE-350150015 | 3.50mm | .138″ | 1.50mm | .059″ | 0.15mm | .0059″ |

| HDY-SHE-400150015 | 4.00mm | .157″ | 1.50mm | .059″ | 0.15mm | .0059″ |

| HDY-SHE-450150015 | 4.50mm | .177″ | 1.50mm | .059″ | 0.15mm | .0059″ |

| HDY-SHE-500200015 | 5.00mm | .197″ | 2.00mm | .079″ | 0.15mm | .0059″ |

| HDY-SHE-600200015 | 6.00mm | .236″ | 2.00mm | .079″ | 0.15mm | .0059″ |

| HDY-SHE-700200020 | 7.00mm | .276″ | 2.00mm | .079″ | 0.20mm | .0079″ |

| HDY-SHE-800200020 | 8.00mm | .315″ | 2.00mm | .079″ | 0.20mm | .0079″ |

| Custom Dimensions Available: Contact us for full specs or specialized OD, strip thickness/width solutions. | |||

中文 (中国)

中文 (中国)  English

English