- Do you need help? Here Us:

- +86 13169905499

- sunny@handaseal.com

- Wechat:13169905499

Chenzhou, Hunan, China(423000))

Full Contact Springs Overview

Handa Full Contact Springs (aka Raco or continuous-contact springs) provide uninterrupted spring contact around the entire sealing circumference, delivering uniform radial pressure for high-integrity seals. Our heavy-duty full contact designs support very high loads and are recommended for extreme environments—cryogenics, vacuum systems, and light-gas applications at low pressures.

*Full contact springs require welding after placement inside the seal jacket.

If a standard size does not meet your requirements, request a custom quote from Handa Spring for tailored cross-sections and materials.

Cusom Full Contact Springs

For over 10 years, we’ve supplied Full Contact Springs to industries worldwide, from aerospace to energy. Our team combines engineering expertise with responsive service—whether you need a standard part or a fully custom design. Off-the-shelf options aren’t always enough. Our custom manufacturing capabilities include:

-

Specialty Materials: From high-grade stainless steels to exotic alloys, we source materials tailored to your environment’s demands (corrosion resistance, temperature tolerance, etc.).

-

Secondary Finishing: Add coatings or treatments to enhance durability, conductivity, or compatibility with specific media.

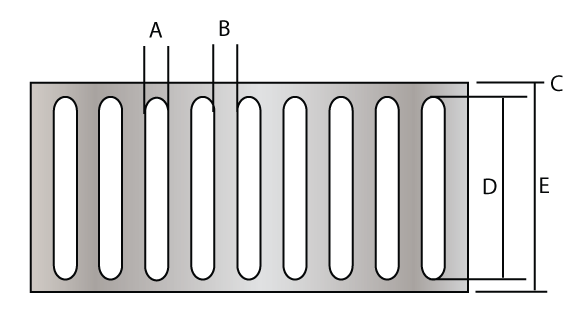

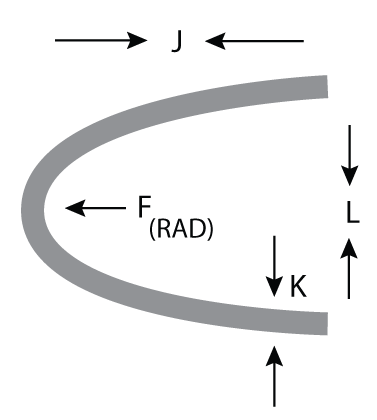

Full Contact Spring Dimensional

| Series | J | K | L |

|---|---|---|---|

| HD-FCS-200 | 5.80 MM | 0.50 MM | 6.60 MM |

| HD-FCS-300 | 7.28 MM | 0.60 MM | 10.0 MM |

You can also contact engineers for customization.

Materials & Plating

Our Handa Spring is available in a variety of materials and surface finishes to meet specific performance demands. To reduce the potential for corrosion between dissimilar metals, we can plate springs with a galvanically compatible material.

Wire Materials Include:

- STAINLESS STEEL (302, 316, 316L)

- HASTELLOY®

- INCONEL®

- Elgiloy®

Plating Options Include:

- GOLD

- SILVER

- NICKEL

Why Partner With Us?

Free Mold Opening

After-Sales Support

Customization Service

Why Full Contact Springs Stand Apart

When reliability in extreme conditions is non-negotiable, Full Contact Springs deliver uncompromising performance. Engineered to provide 360° circumferential contact along sealing lips, these heavy-duty springs ensure consistent force and leak-tight integrity—even in the harshest industrial environments.

-

High-Load Capability: Built for heavy-duty performance, these springs generate robust, uniform force to withstand extreme pressures and dynamic conditions.

-

Extreme Environment Compatibility: Ideal for cryogenics, vacuum systems, and light gas applications at low pressures—where precision sealing is mission-critical.

In summary, Full Contact Springs redefine reliability in sealing applications: their unique 360° contact design eliminates weak points, while robust construction and material versatility ensure consistent performance across extreme temperatures, pressures, and media. Whether for standard setups or custom challenges, they deliver the precision and durability that critical industries demand.

🚀Frequently Asked Questions

Q: What is a canted coil spring used for?

A: It’s used for sealing, electrical contact, and EMI shielding in demanding applications like surgical robots, downhole tools, and high-frequency electronics.

Q: What materials can Handa Spring use for these springs?

A: Common materials include Elgiloy®, Inconel® 625, 316 SS, and Hastelloy® C-276. Plating options include gold, silver, nickel, and tin.

Q: Can I request a custom size or load specification?

A: Yes. Handa Spring supports full customization and prototyping—including free consultation and sample evaluation.

中文 (中国)

中文 (中国)  English

English