- Do you need help? Here Us:

- +86 13169905499

- sunny@handaseal.com

- Wechat:13169905499

Chenzhou, Hunan, China(423000))

Cantilever V Spring Overview

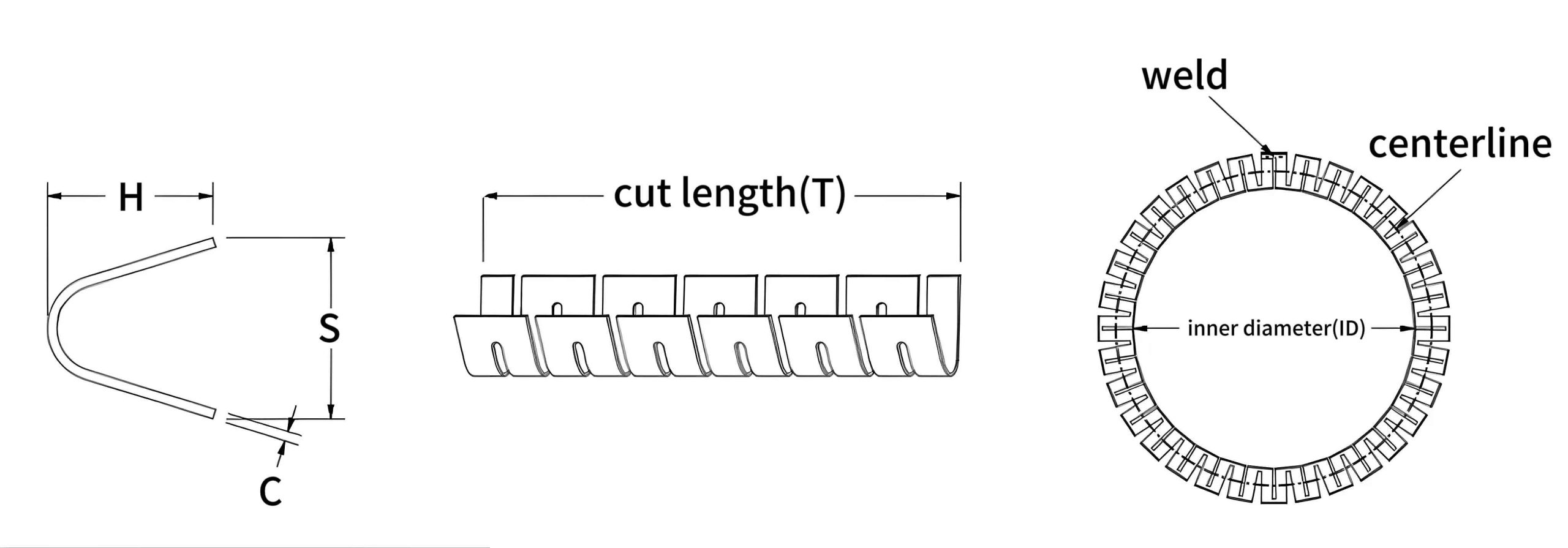

Handa Cantilever V Springs, also known as: V Spring, Meander V Spring, Elgiloy Cantilever Spring, Punch Finger Spring. feature a precise V-shaped profile that delivers an even, linear load across a wide deflection range.

They are suitable for both static sealing and low-to-moderate dynamic motion applications. Manufactured in continuous lengths or custom-cut segments, our V-spring energizers are available in high-performance alloys such as Elgiloy® and Stainless Steel, ensuring excellent corrosion resistance, fatigue life, and sealing reliability in demanding environments.

Cusom Cantilever Springs

Unlock reliable sealing with custom Cantilever V Springs from Handa. We design and manufacture V-spring energizers to your exact specifications—load, deflection, length, and material. With expertise in Elgiloy® and stainless steel, we deliver fast prototyping, flexible batch sizes, and precision performance for demanding aerospace, medical, oil & gas, and industrial applications.

The mold cost will be refunded once total production reaches 10,000 meters, helping you reduce overall expenses. Complete customization based on drawings or samples. Using proven alloys such as Elgiloy®, stainless steel, Inconel X-750, Inconel 718, and 276, our energizers deliver reliable sealing performance for aerospace, medical, oil & gas, and industrial applications.

We can produce custom molds based on the dimensions provided in your drawings.

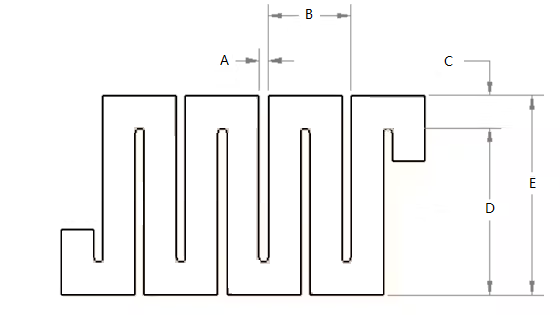

Cantilever Spring Dimensional

The Cantilever V Spring chart below shows the standard dimensions of the Standard V Cantilever/Meander type springs. All dimensions are subject to standard manufacturing print tolerances. Those tolerances may be requested if needed. Each Cantilever V Spring is manufactured in its own standard tool & die set.

However if you are needing more aggressive changes such as width of the raw material or radius dimensions we suggest you inquire about more other nonstandard cross sections of V and U springs.

The table is a part of specification size, more specifications please see attached. You can also contact engineers for customization.

| Series | S(mm | “) | H(mm | “) | C(mm | “) |

|---|---|---|---|

| HDY-CVS-095120010 | 0.95mm | .037″ | 1.20mm | .047″ | 0.10mm | .004″ |

| HDY-CVS-119104008 | 1.19mm | .047″ | 1.04mm | .041″ | 0.08mm | .003″ |

| HDY-CVS-120120010 | 1.20mm | .047″ | 1.20mm | .047″ | 0.08mm | .003″ |

| HDY-CVS-150150008 | 1.50mm | .059″ | 1.50mm | .059″ | 0.08mm | .003″ |

| HDY-CVS-180203013 | 1.80mm | .071″ | 2.03mm | .08″ | 0.13mm | .005″ |

| HDY-CVS-190190008 | 1.90mm | .075″ | 1.90mm | .075″ | 0.10mm | .004″ |

| HDY-CVS-200200012 | 2.00mm | .079″ | 2.00mm | .079″ | 0.12mm | .0047″ |

| HDY-CVS-250250012 | 2.50mm | .098″ | 2.50mm | .098″ | 0.12mm | .0047″ |

| HDY-CVS-280280015 | 2.80mm | .11″ | 2.80mm | .11″ | 0.15mm | .0059″ |

| HDY-CVS-300280012 | 3.00mm | .118″ | 2.80mm | .11″ | 0.12mm | .0047″ |

| HDY-CVS-257267015 | 2.57mm | .101″ | 2.67mm | .105″ | 0.15mm | .0059″ |

| HDY-CVS-350350015 | 3.50mm | .138″ | 3.50mm | .138″ | 0.15mm | .0059″ |

| HDY-CVS-380380020 | 3.80mm | .15″ | 3.80mm | .15″ | 0.20mm | .0079″ |

| HDY-CVS-400400020 | 4.00mm | .157″ | 4.00mm | .157″ | 0.20mm | .0079″ |

| HDY-CVS-439406020 | 4.39mm | .173″ | 4.06mm | .16″ | 0.20mm | .0079″ |

| HDY-CVS-450420018 | 4.50mm | .177″ | 4.20mm | .165″ | 0.18mm | .0071″ |

| HDY-CVS-450450020 | 4.50mm | .177″ | 4.50mm | .177″ | 0.20mm | .0079″ |

| HDY-CVS-480420020 | 4.80mm | .189″ | 4.20mm | .165″ | 0.20mm | .0079″ |

| HDY-CVS-500400015 | 5.00mm | .197″ | 4.00mm | .157″ | 0.15mm | .0059″ |

| HDY-CVS-622597025 | 6.22mm | .245″ | 5.97mm | .235″ | 0.25mm | .0098″ |

| HDY-CVS-808914050 | 8.08mm | .318″ | 9.14mm | .36″ | 0.50mm | .0197″ |

Materials & Plating

Our Handa Cantilever spring is available in a variety of materials and surface finishes to meet specific performance demands. To reduce the potential for corrosion between dissimilar metals, we can plate springs with a galvanically compatible material.

Wire Materials Include:

- STAINLESS STEEL (302, 316, 316L)

- HASTELLOY®

- INCONEL®

- Elgiloy®

Plating Options Include:

- GOLD

- SILVER

- NICKEL

Why Partner With Us?

Free Mold Opening

After-Sales Support

Customization Service

Engineering Excellence You Can Trust

Our Cantilever V Springs solve complex engineering challenges in diverse sectors:

-

Premium Materials: Available in stainless steel (302, 316), Inconel, Hastelloy, and high-carbon steel—selected for corrosion resistance, temperature tolerance (-200°C to +600°C), and strength.

-

Precision Manufacturing: CNC-machined to tight tolerances (±0.001″) with advanced heat treatment for optimal spring properties.

-

Compliance & Certification: Meet ISO 9001 with full material traceability.

-

Rapid Prototyping: Get custom prototypes in 5–7 days to test fit, form, and function before full-scale production.

🚀Frequently Asked Questions

Q: What is a canted coil spring used for?

A: It’s used for sealing, electrical contact, and EMI shielding in demanding applications like surgical robots, downhole tools, and high-frequency electronics.

Q: What materials can Handa Spring use for these springs?

A: Common materials include Elgiloy®, Inconel® 625, 316 SS, and Hastelloy® C-276. Plating options include gold, silver, nickel, and tin.

Q: Can I request a custom size or load specification?

A: Yes. Handa Spring supports full customization and prototyping—including free consultation and sample evaluation.

中文 (中国)

中文 (中国)  English

English