- Do you need help? Here Us:

- +86 13169905499

- sunny@handaseal.com

- Wechat:13169905499

Chenzhou, Hunan, China(423000))

Canted Coil Spring Overview

Choosing the right Canted Coil Spring is essential to achieving reliable performance, especially in high-precision sealing, electrical contact, and EMI/RFI shielding applications. At Handa Seal, we help B2B customers—from aerospace OEMs to medical device engineers—select or customize the ideal spring based on a range of technical requirements.

At Handa Seal, we design and manufacture premium Canted Coil Springs engineered to deliver consistent force, EMI shielding, and leak-tight sealing in demanding environments. Two of the most critical industries that rely on our technology are medical devices and oil & gas equipment. With a combination of material versatility, engineering expertise, and tight tolerance production, our spring solutions ensure maximum reliability and performance in life-saving and mission-critical systems.

Canted Coil Spring Service Types

One Component, Four FunctionsCanted Coil Spring Design

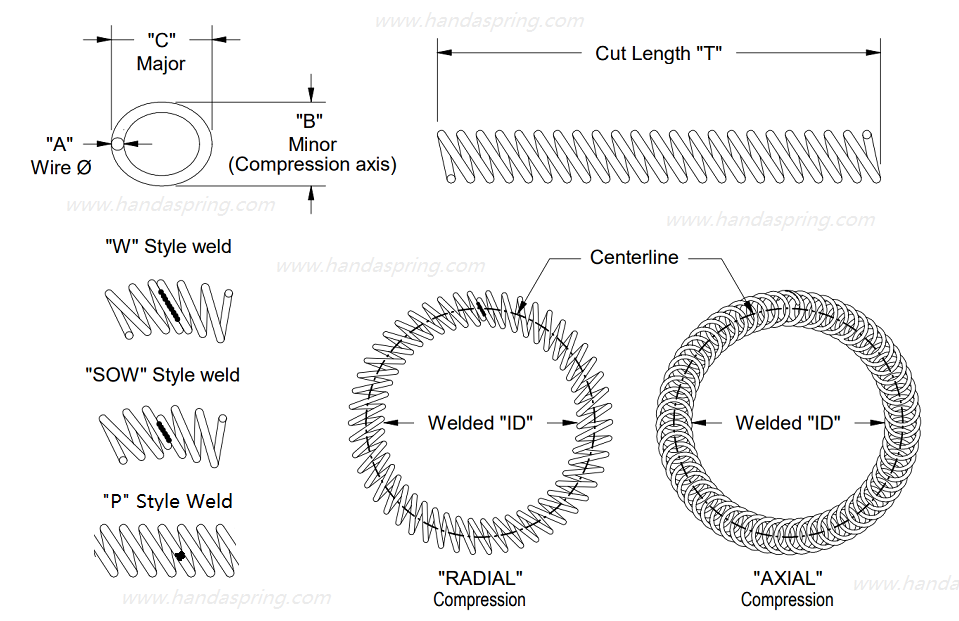

The most visible difference between a canted coil spring and other spring types is its cross-section, which is elliptical or oval, not circular. Key design characteristics of the spring are its wire diameter (A), coil height (B), coil width (C), coil spacing, Welded Inner Dimensional(ID). Each of these can be precisely adjusted to influence force, electrical contact resistance, and other properties. The orientation of a spring’s coils in relation to the centerline determines whether it is axial or radial. Compression force for a radial canted coil spring is along the radius of the arc or ring, perpendicular to the centerline. Compression force for an axial canted coil spring is along the axis of the arc or ring, parallel to the centerline.

Dimensional Data

We can produce custom-made slant coil springs in nearly any size based on your samples or drawings.

Min Size Range:

-

B/C sizes ≈Ø0.4mm(0.0157″)

-

ID=1mm(0.039″)

***If you can’t find the geometry you’d like in the table below, a unique toolset can be designed specifically for your application. Ask an Handa expert for details.

| Series | Typical Load | “A” (Wire OD) |

“B” (Width) |

“C” (Height) |

“T” (Cut Length) |

“ID” |

|---|---|---|---|---|---|---|

| HD-CS-L132 | L | 0.08 | 0.62 | 0.70 | 7.60 | 1.80 |

| HD-CS-M132 | M | 0.10 | 0.62 | 0.70 | 7.60 | 1.80 |

| HD-CS-H132 | H | 0.12 | 0.65 | 0.75 | 7.70 | 1.80 |

| HD-CS-L000 | L | 0.12 | 1.40 | 1.55 | 12.90 | 2.70 |

| HD-CS-M000 | M | 0.15 | 1.40 | 1.55 | 12.90 | 2.70 |

| HD-CS-H000 | H | 0.20 | 1.20 | 1.32 | 12.20 | 2.70 |

| HD-CS-L100 | L | 0.18 | 2.00 | 2.40 | 19.80 | 4.30 |

| HD-CS-M100 | M | 0.35 | 2.00 | 2.40 | 20.10 | 4.40 |

| HD-CS-H100 | H | 0.35 | 2.00 | 2.30 | 19.80 | 4.30 |

| HD-CS-L200 | L | 0.30 | 2.80 | 3.20 | 30.10 | 6.80 |

| HD-CS-M200 | M | 0.35 | 2.80 | 3.20 | 30.10 | 6.80 |

| HD-CS-H200 | H | 0.40 | 2.80 | 3.20 | 30.10 | 6.80 |

| HD-CS-L300 | L | 0.40 | 4.00 | 4.50 | 42.70 | 9.60 |

| HD-CS-M300 | M | 0.50 | 4.00 | 4.50 | 42.70 | 9.60 |

| HD-CS-H300 | H | 0.60 | 4.00 | 4.50 | 42.70 | 9.60 |

| HD-CS-L400 | L | 0.50 | 5.50 | 6.00 | 61.20 | 14.00 |

| HD-CS-M400 | M | 0.60 | 5.50 | 6.00 | 61.20 | 14.00 |

| HD-CS-H400 | H | 0.70 | 5.50 | 6.00 | 61.20 | 14.00 |

| HD-CS-L500 | L | 0.60 | 8.20 | 9.20 | 96.40 | 22.50 |

| HD-CS-M500 | M | 0.70 | 8.20 | 9.20 | 96.40 | 22.50 |

| HD-CS-H500 | H | 1.00 | 8.20 | 9.20 | 96.40 | 22.50 |

| HD-CS-L600 | L | 0.70 | 11.40 | 12.80 | 152.00 | 37.00 |

| HD-CS-M600 | M | 1.00 | 11.40 | 12.80 | 152.00 | 37.00 |

| HD-CS-H600 | H | 1.20 | 11.40 | 12.80 | 152.00 | 37.00 |

Materials & Plating

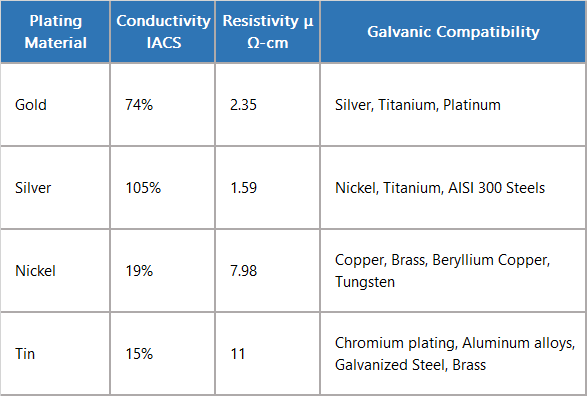

Our Handa canted coil spring is available in a variety of wire materials and surface finishes to meet specific performance demands. To reduce the potential for corrosion between dissimilar metals, we can plate springs with a galvanically compatible material.

Wire Materials Include:

- STAINLESS STEEL (302, 316, 316L)

- MP35N®

- PLATINUM IRIDIUM

- TITANIUM

- HASTELLOY®

- INCONEL®

- BERYLLIUM-COPPER

- ZIRCONIUM-COPPER

Plating Options Include:

- GOLD

- SILVER

- NICKEL

- TIN

How a Canted Coil Spring Works

Canted coil springs, are engineered to deliver consistent force, uniform contact pressure, and multi-directional load support. At Handa Spring, we specialize in designing and manufacturing custom canted coil springs that meet the highest performance standards for demanding applications.

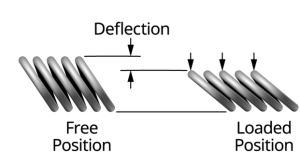

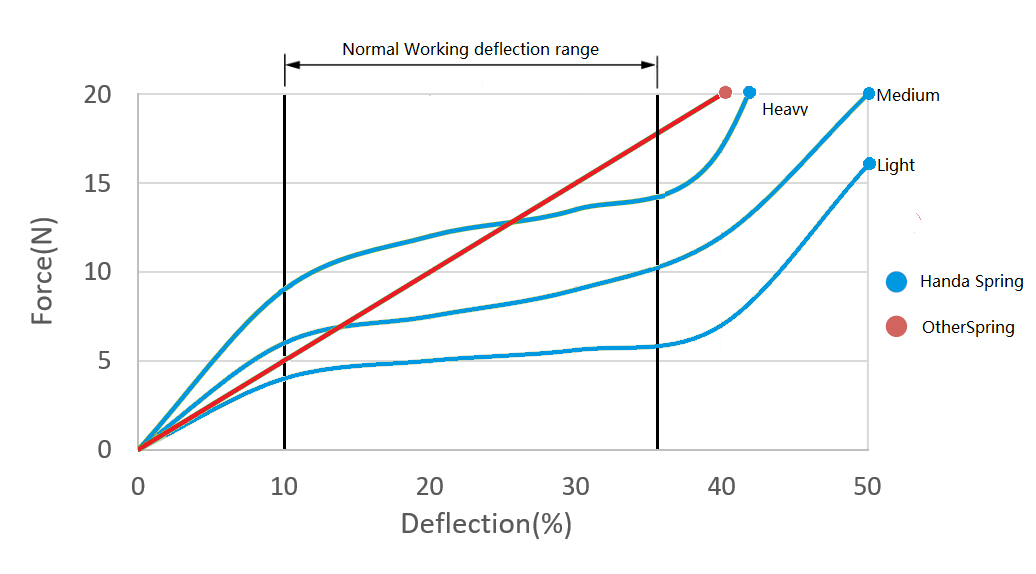

1.Constant Force Through Working Deflection Range

As the spring is further compressed, its load remains relatively constant throughout the working deflection range. This continues until the maximum deflection point, where the individual coils come into contact with one another. Beyond this point, no further deflection is possible.

Unlike traditional sealing elements such as O-rings or V-springs, which exert a force that increases proportionally with deflection, Handa’s canted coil springs provide only the required force needed for mechanical retention or electrical conductivity. This results in:

- Lower insertion and breakaway forces

- Reduced component wear

- Longer operational cycle life

This constant force profile is especially valuable in applications involving high mating cycles or sensitive assemblies.

2.Electrical Design Considerations

In electrical and EMI shielding applications, the performance of a canted coil spring depends not only on its geometry but also on the material and surface finish. Key design factors include:

- Base wire material (e.g., stainless steel, Elgiloy®, beryllium copper)

- Plating material (e.g., gold, silver, nickel)

- Plating thickness

Applying a conductive plating layer over the spring’s wire significantly enhances its electrical conductivity, improves signal integrity, and ensures consistent grounding.

At Handa Spring, we offer a range of plating options to match your specific performance and corrosion resistance requirements.

Featured Industries: Medical and Oil & Gas

Canted Coil Springs in Medical Applications

Canted coil springs, or slant coil springs are extensively used in the medical industry for their precise, repeatable force and ability to provide reliable connections in critical applications – specifically quick connect/disconnect. With customizable load and deflection characterized, canted coil springs can provide fast, secure connections in critical applications such as surgical instruments and diagnostic equipment.

Canted coil springs are also commonly used as electrical connectors and spring energized seals. As electrical connectors, canted coil springs help provide secure, low-resistance connections in implantable devices like pacemakers and neurostimulators, where consistent performance is essential. When used as a sealing tool, canted coil springs are paired with a polymer jacket, often made from biocompatible materials like PTFE or UHMWPE, and are used in medical devices such as infusion pumps, ventilators, surgical instruments, and diagnostic equipment, where precision and cleanliness are paramount. In these applications, spring-energized seals guard against leaks under changing conditions, such as repeated movements or pressure fluctuations, while withstanding exposure to sterilization processes, chemicals, and biofluids.

In addition to mechanical locking or holding applications, connecting for optimum electrical conductivity is possible due to the small coil size and the number of independent coils. In regard to EMI/RFI shielding applications, the canted or slant coil spring offers an economical design option that can reduce radiated and conducted interference to prevent premature failure in electrical devices. Electromagnetic and radio frequency interference can be very dangerous for medical equipment, having the potential to disrupt its normal operation or comprise the integrity of data transmitted or received. For this reason, you will often find canted coil springs in electrical enclosures or used with data transmission cables. These springs can be customized and tuned to meet impedance specifications to protect equipment from crosstalk interference.

Canted Coil Springs in Oil & Gas Applications

Canted coil springs are frequently used as spring energized seals to ensure leak-proof performance in extreme environments such as those found in the oil & gas industries. In sealing applications, canted coil springs are combined with a durable polymer jacket, often made from materials like PTFE, to provide exceptional resistance to high pressures, extreme temperatures, and corrosive chemicals.

Commonly used in valves, pumps, compressors, and downhole tools, canted coil springs help maintain a tight seal even under dynamic conditions, such as rotational or reciprocating motion. The spring ensures continuous contact between the seal and the mating surface, compensating for wear, pressure fluctuations, and misalignments. By preventing leaks and maintaining system integrity, spring-energized seals enhance the safety, efficiency, and longevity of critical oil and gas equipment.

🚀Frequently Asked Questions

Q: What is a canted coil spring used for?

A: It’s used for sealing, electrical contact, and EMI shielding in demanding applications like surgical robots, downhole tools, and high-frequency electronics.

Q: What materials can Handa Spring use for these springs?

A: Common materials include Elgiloy®, Inconel® 625, 316 SS, and Hastelloy® C-276. Plating options include gold, silver, nickel, and tin.

Q: Can I request a custom size or load specification?

A: Yes. Handa Spring supports full customization and prototyping—including free consultation and sample evaluation.

中文 (中国)

中文 (中国)  English

English