- Phone:

- +86 13169905499

- sunny@handaseal.com

- Wechat:13169905499

Chenzhou, Hunan, China(423000))

Why Full Contact Springs Stand Apart

A cantilever V spring is defined by its distinctive “V” shape and single-point mounting, combining the rigidity of a cantilever design with the flexibility of a coiled spring. This unique structure offers:

-

Specialty Materials: From high-grade stainless steels to exotic alloys, we source materials tailored to your environment’s demands (corrosion resistance, temperature tolerance, etc.).

-

High-Load Capability: Built for heavy-duty performance, these springs generate robust, uniform force to withstand extreme pressures and dynamic conditions.

-

Extreme Environment Compatibility: Ideal for cryogenics, vacuum systems, and light gas applications at low pressures—where precision sealing is mission-critical.

-

Ready-to-Use Design: Available in continuous lengths, shipped pre-cut and ready to roll to your exact diameter (welding required after placement in the seal jacket).

In summary, Full Contact Springs redefine reliability in sealing applications: their unique 360° contact design eliminates weak points, while robust construction and material versatility ensure consistent performance across extreme temperatures, pressures, and media. Whether for standard setups or custom challenges, they deliver the precision and durability that critical industries demand.

Custom Solutions for Unique Requirements

Off-the-shelf options aren’t always enough. Our custom manufacturing capabilities include:

-

Specialty Materials: From high-grade stainless steels to exotic alloys, we source materials tailored to your environment’s demands (corrosion resistance, temperature tolerance, etc.).

-

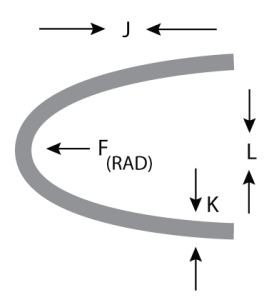

Non-Standard Sizes: With over 100 nonstandard cross-sections and custom tooling options, we can engineer springs to fit unique geometries—even minor adjustments to “L” and “K” dimensions or aggressive changes to material width and radii.

-

Secondary Finishing: Add coatings or treatments to enhance durability, conductivity, or compatibility with specific media.

Request a custom quote to share your specs—our engineers will design a solution that fits perfectly.

Standard Dimensional Data

Choose from our proven standard series, with both imperial and metric options:

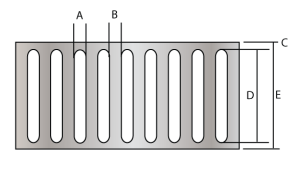

| Series | A | B | C | D | E | F | J | K | L |

|---|---|---|---|---|---|---|---|---|---|

| HD-FCS-200 | 1.27 MM | 1.27 MM | 0.99 MM | 5.13 MM | 7.11 MM | 0.61 MM | 3.45 MM | 0.36 MM | 3.40 MM |

| HD-FCS-300 | 1.27 MM | 1.27 MM | 1.33 MM | 7.92 MM | 10.59 MM | 0.76 MM | 4.83 MM | 0.51 MM | 4.57 MM |

| HD-FCS-400 | 1.27 MM | 1.27 MM | 1.80 MM | 9.58 MM | 13.18 MM | 1.52 MM | 5.87 MM | 0.51 MM | 6.60 MM |

| HD-FCS-500 | 1.27 MM | 1.27 MM | 2.67MM | 12.57 MM | 17.91 MM | 3.05 MM | 7.24 MM | 0.64 MM | 10.03 MM |

Partner With Handa Seal

For over 10 years, we’ve supplied Full Contact Springs to industries worldwide, from aerospace to energy. Our team combines engineering expertise with responsive service—whether you need a standard part or a fully custom design.

Get Started Today:

-

Request a quote for custom specifications

-

Download our full dimensional catalog

-

Consult with an engineer about your application

🚀Frequently Asked Questions

Q: What materials can Handa Spring use for these springs?

A: Common materials include Elgiloy®, Inconel® 625, 316 SS, and Hastelloy® C-276. Plating options include gold, silver, nickel, and tin.

Q: Can I request a custom size or load specification?

A: Yes. Handa Spring supports full customization and prototyping—including free consultation and sample evaluation.

English

English  中文 (中国)

中文 (中国)