- Phone:

- +86 13169905499

- 455396866@qq.com

- Wechat:13169905499

Chenzhou, Hunan, China(431000))

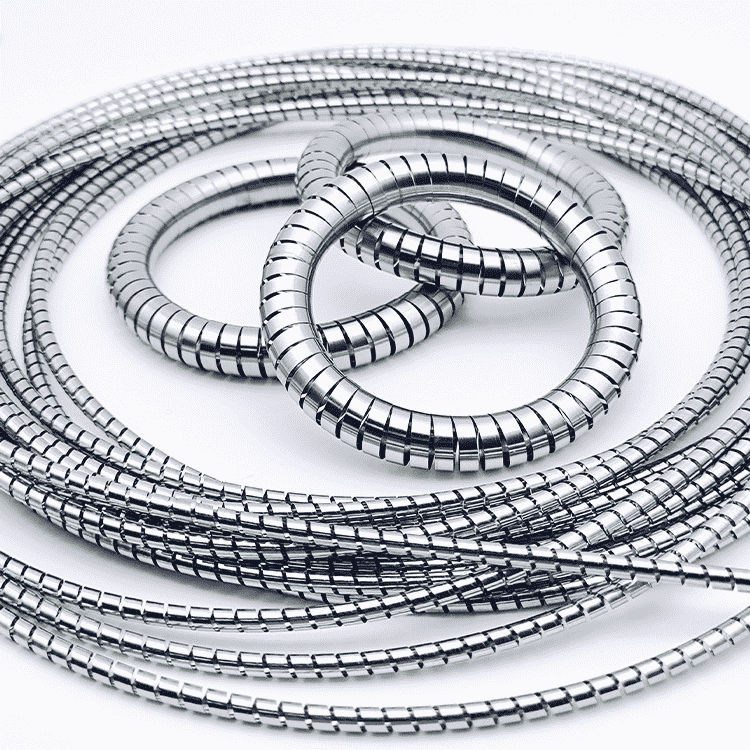

Helical Wound Springs Overview

The Helical Spring Seal is a continuous wound energizer designed to exert consistent radial or axial load within polymeric or metallic sealing jackets. Its coiled geometry delivers uniform deflection characteristics, making it ideal for maintaining long-term sealing force in both static and dynamic environments.

Compared to Cantilever Spring or canted coil designs, helical spring energizers offer smoother load curves, improved stress distribution, and enhanced fatigue life. This makes them especially suitable for high-cycle, high-precision sealing systems in compact or extreme environments.

Claim Your Free Sample Now!!!

Custom & Helical Spring Dimensional Data

Reference the below to find dimensions for our standard Helical springs. Custom diameters, widths, and thicknesses can also be created. No additional tooling charges are required for special diameters or alternate material slit widths. Special material requirements for 17-7 PH Stainless are available and can be supplied in two weeks or less. The following Elgiloy strip thicknesses and widths are also in stock and available without minimums.

| SERIES | S(Outside diameter) | H(Width) | C(Material thickness) |

|---|---|---|---|

| HDY-SHE-152038010 | 1.52mm | .06″ | 0.38mm | .015″ | 0.10mm | .0039″ |

| HDY-SHE-200150010 | 2.00mm | .079″ | 1.50mm | .059″ | 0.10mm | .0039″ |

| HDY-SHE-229051013 | 2.29mm | .09″ | 0.51mm | .02″ | 0.13mm | .005″ |

| HDY-SHE-250150010 | 2.50mm | .098″ | 1.50mm | .059″ | 0.10mm | .0039″ |

| HDY-SHE-300150010 | 3.00mm | .118″ | 1.50mm | .059″ | 0.10mm | .0039″ |

| HDY-SHE-318064020 | 3.18mm | .125″ | 0.64mm | .025″ | 0.20mm | .0079″ |

| HDY-SHE-318150015 | 3.18mm | .125″ | 1.50mm | .059″ | 0.15mm | .0059″ |

| HDY-SHE-350150015 | 3.50mm | .138″ | 1.50mm | .059″ | 0.15mm | .0059″ |

| HDY-SHE-400150015 | 4.00mm | .157″ | 1.50mm | .059″ | 0.15mm | .0059″ |

| HDY-SHE-450150015 | 4.50mm | .177″ | 1.50mm | .059″ | 0.15mm | .0059″ |

| HDY-SHE-500200015 | 5.00mm | .197″ | 2.00mm | .079″ | 0.15mm | .0059″ |

| HDY-SHE-600200015 | 6.00mm | .236″ | 2.00mm | .079″ | 0.15mm | .0059″ |

| HDY-SHE-700200020 | 7.00mm | .276″ | 2.00mm | .079″ | 0.20mm | .0079″ |

| HDY-SHE-800200020 | 8.00mm | .315″ | 2.00mm | .079″ | 0.20mm | .0079″ |

| Custom Dimensions Available: Contact us for full specs or specialized OD, strip thickness/width solutions. | |||

Material Options

We offer a broad selection of corrosion-resistant and high-performance alloys to ensure optimal spring function across temperature extremes and aggressive media.

- Inconel® 718 – High strength and oxidation resistance up to 650°C, ideal for energy, aerospace, and cryogenic sealing

- Elgiloy® – Superior fatigue resistance and corrosion performance, preferred in dynamic or mission-critical seals

- Hastelloy® C-276 – Exceptional resistance to oxidizing acids and aggressive chemicals, suitable for process control and semiconductor systems

- 17-7PH Stainless Steel – Balanced strength and corrosion resistance for general-purpose industrial use

- Other Material – Contact Us

We select materials based on operating temperature, chemical compatibility, and certification requirements (e.g., NACE, FDA, or ASME standards).

Features & Benefits

Helical Spring Seals deliver consistent and repeatable sealing force with minimal stress loss, making them ideal for high-performance static and dynamic sealing applications.

Uniform spring rate supports precise sealing force control

Minimal stress relaxation over extended use

Excellent recovery after thermal and mechanical cycling

Material and geometry customizable to match seal jacket design

Long service life under chemical, vacuum, or pressure exposure

Applications

Our Helical Spring Seals are deployed in systems where sealing reliability under thermal, chemical, or dynamic stress is critical to performance and safety.

- Aerospace: fuel delivery systems, engine components, and actuator seals

- Medical: sterilizer valves, fluidic control in surgical and diagnostic devices

- Energy: hydrogen handling, LNG compression, geothermal and nuclear sealing

- Semiconductor: vacuum chamber interfaces, wafer transfer sealing, UHV equipment

- Industrial Automation: robotic arm sealing, hydraulic or pneumatic rotary joints

Frequently Asked Questions

English

English  中文 (中国)

中文 (中国)